Solar panel recycling is important in the energy industry because it addresses the environmental and economic concerns associated with disposing of outdated solar panels. With the ongoing increase in worldwide energy installations, a significant number of solar panels will soon approach their end-of-life phase, leading to the generation of trash.

Recycling these panels may prevent the release of harmful compounds into landfills, thereby avoiding environmental pollution. Additionally, recycling offers the chance to reclaim valuable resources and generate employment opportunities in the green sector. Recycling panels allows us to effectively preserve resources often used in the production of new panels. This not only helps to alleviate constraints in the supply chain but also diminishes the requirement for mining raw materials.

Market Value of Recyclable material

According to the International Renewable Energy Agency, the worldwide market value of recyclable raw materials from end-of-life solar panels will reach $450 million by 2030, which is comparable to the cost of using the same raw materials to make 60 million new panels. Recycling solar panels saves landfill space and recovers their value.

How many years can solar panels last?

Research indicates that the average lifespan of solar panels is around 30 years prior to their decommissioning.

Over the lifespan of solar panels, there may be a reduction of 20 percent in their power capacity. During the initial 10 to 12 years, the efficiency can fall by a maximum of 10 percent, and by 20 percent when the system reaches 25 years of age. Even the most efficient solar panels are not immune to this phenomenon.

Does cleansing increase efficiency of solar panels? However, empirical evidence demonstrates that, in actuality, the efficiency decreases by just 6 to 8 percent after 25 years. As a result, the lifespan of solar panels may exceed the officially declared duration. High-quality PV panels have a lifespan of 30 to 40 years and can still function afterwards, though with reduced effectiveness.

What happened if solar panel waste not dispose properly?

By 2050, landfills would receive approximately 60 million tons of PV panel waste in the absence of recycling processes. This would be an unsustainable method of obtaining energy, as all PV cells contain varying amounts of toxic substances.

It is a misconception to believe that solar panels cannot undergo recycling. However, implementing recycling methods on a large scale necessitates time and additional research to effectively recycle all components of solar panels. Therefore, close collaboration between design and recycling units is necessary to develop environmentally conscious designs that facilitate recycling.

Which Solar panel material can be recycled?

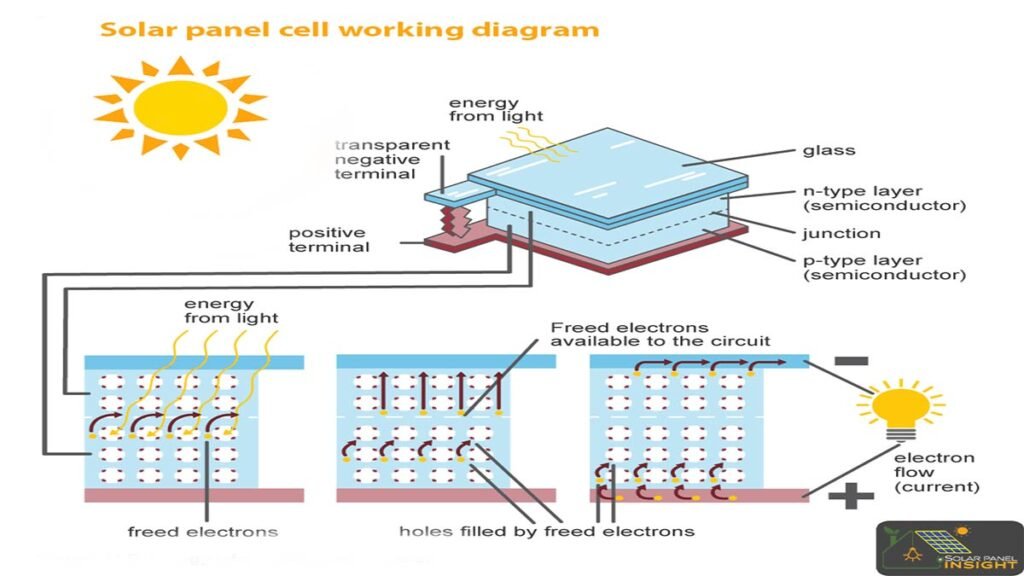

Crystalline-silicon technology primarily dominates the solar panel market. Silicon solar cells, a polymer junction box, copper wiring, glass, aluminum frames, and additional polymer layers compose this type of solar panel. We apply the polymer layers to shield the panel from the elements. However, because high temperatures are required to dissolve the glue, recycling and disassembling the panel can be more difficult.

Many of these parts are important because of their recyclability. About three-quarters of a solar panel’s mass is glass. Additionally, there is a well-established glass recycling sector. In addition to the plastic junction box, the aluminium frame and copper cable are also recyclable. It may be more difficult to recycle other parts of the solar cells. Despite their minute amounts, panels’ silver and internal copper play a crucial role. Toxic metals like lead and cadmium could be present in solar panels.

Certain thin-film modules may contain essential elements such as gallium, indium, antimony, tellurium, tin, and aluminium.

Solar power systems can also include inverters, racking, and battery backup systems—all of which are recyclable. You can recycle inverters with other electrical debris, and you can recycle racking with various scrap metals. Current battery recycling processes can manage grid energy storage systems that rely on batteries.

How solar panels are recycled? Recycling process

Different recycling methods are required for the two most common varieties of solar panels. It is possible to recycle both the silicon-based and the thin-film-based varieties using separate industrial procedures. Even if panels made of silicon are more popular right now, that doesn’t imply the materials used in thin-film cells couldn’t be very valuable. Research into solar panel recycling has led to the development of many technologies. Even if some of them achieve a staggering 96% recycling efficiency, we intend to set even better standards moving forward.

As part of their commitment to constant development, researchers and innovators are putting in long hours. In an effort to boost efficiency and cut down on material loss, they are looking into new methods like solvent-based recycling. Furthermore, developments in robotics and artificial intelligence simplify disassembly and sorting operations, increasing recycling efficiency and effectiveness.

i. Recycling of solar panels made from silicon

Disassembling silicon-based PV panels to separate their glass and aluminium components is the first step in the recycling process. We can recycle 95 percent of the glass and reuse all the metal parts used to make the cell frames. In order to make the bonding between the cell elements easier, we heat treat the remaining components at 500 °C. The plastic encasing the silicon cells melts at these high temperatures, exposing them to the next stage of processing. Thanks to supplementary technology, even this plastic goes unused. We then use it as a fuel for further thermal processing, thereby enhancing its reuse.

After heat treatment, we physically separate the green hardware. We can simply repurpose 80% of these things, while processing the remaining 20% to increase their quality. Using acid, etching removes silicon particles, also known as wafers, from a surface. We achieve an astounding 85% recycling rate for the silicon material by melting down and reusing damaged wafers to make new silicon modules.

ii. Recycling of solar panels based on thin-film technology

On the other hand, the processing that thin-film-based panels go through is far more extensive. Shredding them is the initial step. After that, we use a hammer mill to make sure that no particle is bigger than four or five millimeters. This operation breaks the lamination that binds the internal components together, allowing for their removal. The remaining part is a hybrid of solid and liquid materials, which is different from PV panels made of silicon. Centrifugal screws separate solids from liquids by spinning them in a tube while collecting the liquid in a container.

Precipitation and dewatering are processes that liquids go through to guarantee their purity. We use metallurgical processing to completely separate the semiconductor components from the resulting compound. Typically, we recycle 95% of the semiconductor material, but the specific process varies depending on the panel-making technique. Because of their relatively low density, interlayer materials contaminate the solid, but a vibrating surface can remove them. We perform a final rinse on the material. Glass makes up the entire residue, making it simple to re-manufacture 90% of the glass components.

Recycling market of solar panels

Panel recycling is still a relatively new market, but it is continuously growing. Scientists are actively developing recycling methods that could efficiently and cost-effectively recover the majority of a solar panel’s parts. Several countries have enacted legislation to enforce the reuse and recycling of PV panels. Other countries are also prioritizing photovoltaic waste management. The worldwide market for recycling solar panels is experiencing an increase in growth. The market’s valuation in 2022 amounted to £250 million. By 2028, we expect the estimated value to reach £1.29 billion.

Recycling these panels can provide a supply of elements that would otherwise require mining, promoting a more sustainable approach to solar energy as the quantity of discarded solar panels continues to rise. Presently, the situation of solar panel recycling in the UK is somewhat restricted, with only a few companies offering services and insufficient infrastructure to handle the increasing amount of solar waste. Notable recycling service providers in the UK include H&H Pro, ILM Highland, and Recycle Solar Technologies.

The upcoming decade will see the United Kingdom produce approximately 30,000 metric tons of garbage. Additionally, as older solar panels from the turn of the millennium begin to degrade, we anticipate a significant increase in the number of solar panels entering the market throughout the 2030s. This necessitates an expansion of the panel recycling sector’s capabilities to handle the growing number of obsolete panels and aid in the production of solar panels.

Solar waste management’s future benefits

Having established the recyclability of solar panels, the question arises as to whether they offer any additional economic benefits. We must implement an efficient solar panel recycling system to manage the substantial quantities of PV modules that we will soon discard. Once we establish this system, we will observe numerous favourable variables and novel economic prospects.

By 2050, PV recycling is projected to generate a significant amount of recoverable value, estimated at around £11 billion, while also creating several job possibilities in the green sector. This infusion could lead to the production of two billion additional panels, thereby reducing the need for additional raw material expenditures. This suggests that recycling old materials could potentially generate about 630 gigawatts of power.

More and more homes and businesses are choosing to install solar power systems as a result of the steady drop in the price of solar panels. As a result, the business prospects for solar cell recycling will improve.

Conclusion

Solar panel recycling is crucial in the energy industry to address environmental and economic concerns associated with disposing of outdated solar panels. With the increasing number of solar panels approaching their end-of-life phase, recycling can prevent harmful compounds from entering landfills, reclaim valuable resources, and generate employment opportunities in the green sector. The worldwide market value of recyclable raw materials from end-of-life solar panels is expected to reach $450 million by 2030.

Solar panels can last around 30 years before decommissioning, but efficiency may decrease by 6–8 percent after 25 years. By 2050, landfills could receive 60 million tons of PV panel waste, making recycling a sustainable method. Solar panel recycling involves disassembling silicon-based panels, heating them at 500 °C to improve bonding, and repurposing the remaining metal parts. Thin-film-based panels undergo more extensive processing, including shredding, hammer milling, precipitation, dewatering, and metallurgical processing.

The global market for recycling solar panels is growing, with an estimated value of £1.29 billion by 2028. The UK currently faces limited recycling services, but the industry is expected to grow significantly by 2050. By 2050, PV recycling is projected to generate £11 billion in recoverable value and create jobs in the green sector. The rising cost of solar panels is also driving more homes and businesses to adopt solar power systems.

The way you put together the information on your posts is commendable. I would highly recommend this site.

Thank you so much. For more details about the solar energy keep visiting https://solarpanelinsight.com/ regularly.

An excellent read that will keep readers to enhance their knowledge about green energy. thanks

Great site with quality based content.

It is a pleasure to read this weblog, thanks to its up-to-date information and interesting posts.